Protecting Power Supplies from Over-Current Conditions

To ensure a lifetime of safe and reliable operation, power supplies are fitted with various protection mechanisms. Some of these limit the current delivered under short-circuit failure conditions, ensuring that the power supply’s components don’t overheat or break down, allowing the unit to return to normal operation once the fault has been removed. However, some use cases and loads, under certain conditions, can trigger these protection mechanisms. This can lead to confusion as to the source of a fault. To understand whether it is the power supply or the equipment it is powering that is at fault, it is essential to understand the protection mechanisms used and their limitations.

What is a short circuit?

Most engineers have experienced the fallout of a short circuit at some point. The bare end of a wire touches a grounded casing, and – pop – a component’s magic smoke is released. But, when designing a power supply, it is necessary to define what a short circuit is to design appropriate protection circuitry. A short circuit is typically defined as a connection with a resistance below 1 Ω or a shunt resistance that results in the output voltage dropping below 100 mV. In a single output power supply, the short circuit would be between +VOUT and -VOUT.

Protection methods range from constant current limiting and fold-back current limitation to hiccup mode protection. However, it is not necessarily apparent to the user that the protection has been triggered, making it difficult to determine the cause of a fault. Furthermore, some loads, such as capacitors and motors, look electrically like short circuits under some conditions.

How does constant current limiting work?

In the event of a short circuit, power supplies using constant current limiting reduce their output voltage to almost zero while delivering the same current. When measured, a few millivolts may be present. Under these conditions, the protection circuitry ensures that no damage occurs to the output transistors of the power supply. The unit will survive such conditions indefinitely and ensure safety when operated unattended.

It is essential to understand that this differs from the constant current overload protection some power supplies offer. The data sheet may specify a constant current mode for an output current of 105 – 130% of the maximum rated output. However, long-term operation under such conditions will destroy a power supply.

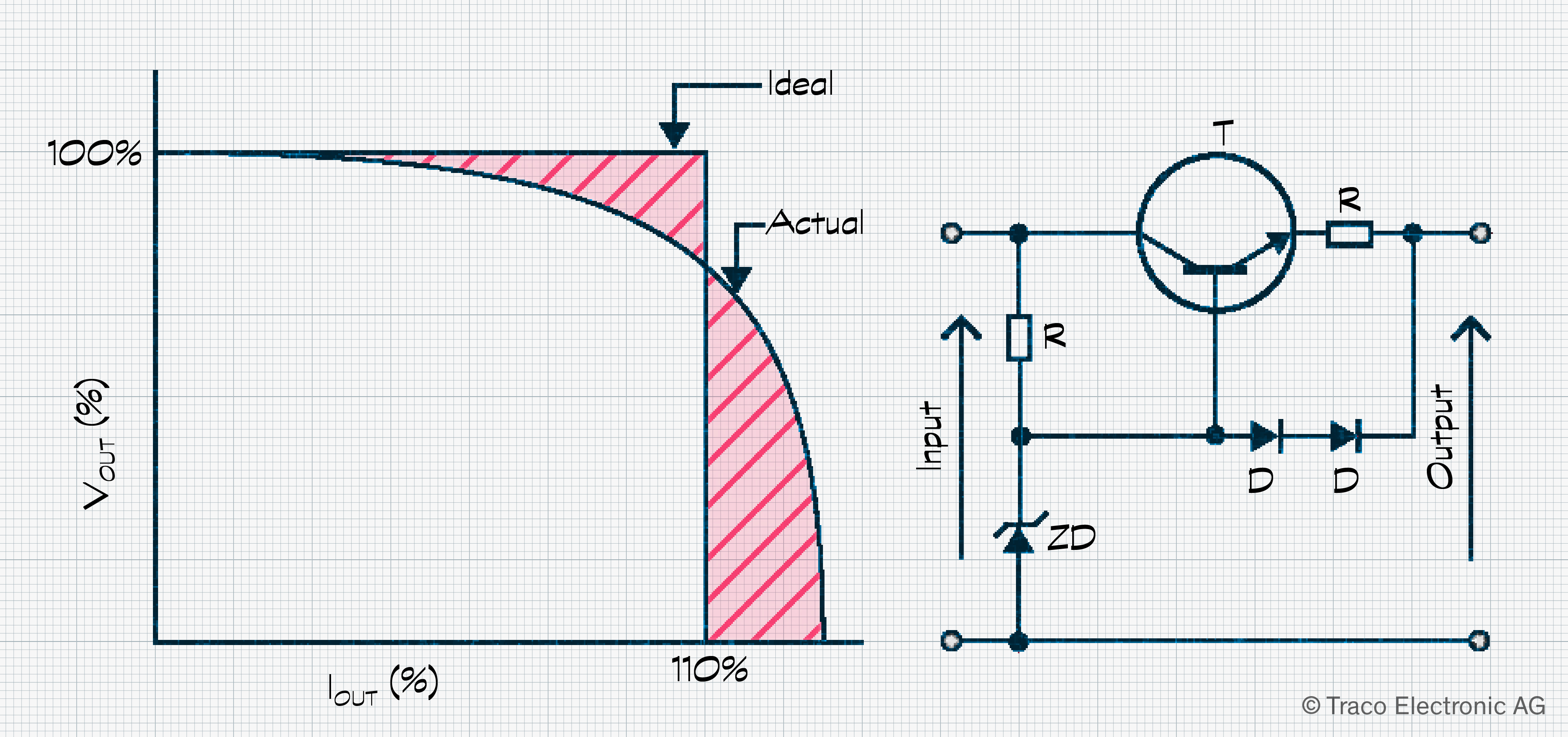

What protection does fold-back current limiting offer?

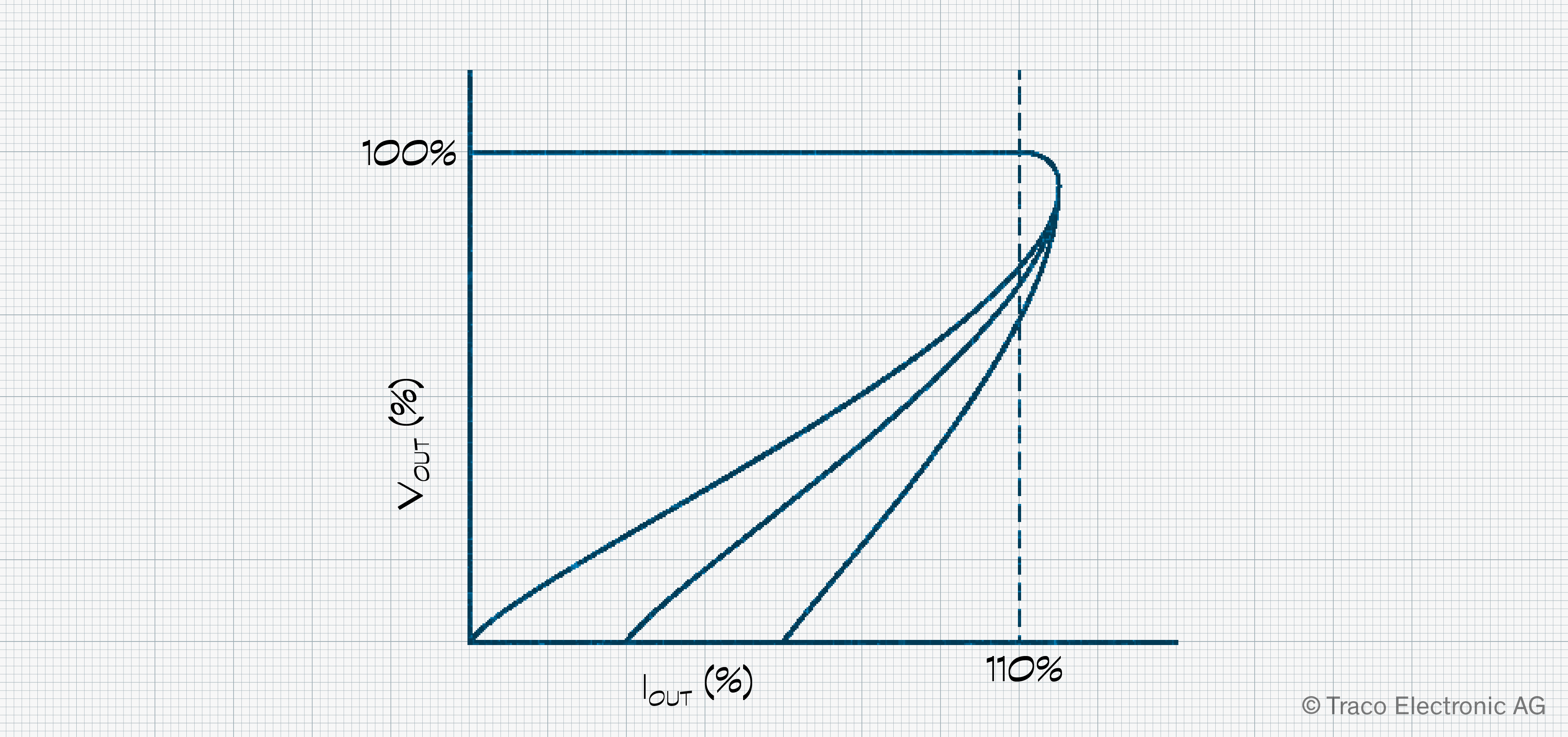

An alternative protection mechanism is fold-back current limiting. This reduces the current and voltage once the current draw exceeds a predefined value. As more current is drawn, both current and voltage are reduced further. Because this mechanism is not universally defined, power supply designers are free to implement it as best suits the application. When fault finding such equipment, it can cause confusion as the voltage and current appear to be outside the data sheet specification.

Suppose the application regularly draws more than the specified maximum current, but the levels are not high enough to be considered a short circuit. In such cases, the power supply risks permanent damage or failure. Under true short circuit conditions, fold-back current limiting provides better output transistor protection for the power supply than the constant-current limit approach.

Non-linear and non-ohmic loads can, however, cause issues. The large inrush current such loads cause can result in lockout, a situation where the power supply engages current limiting but cannot exit.

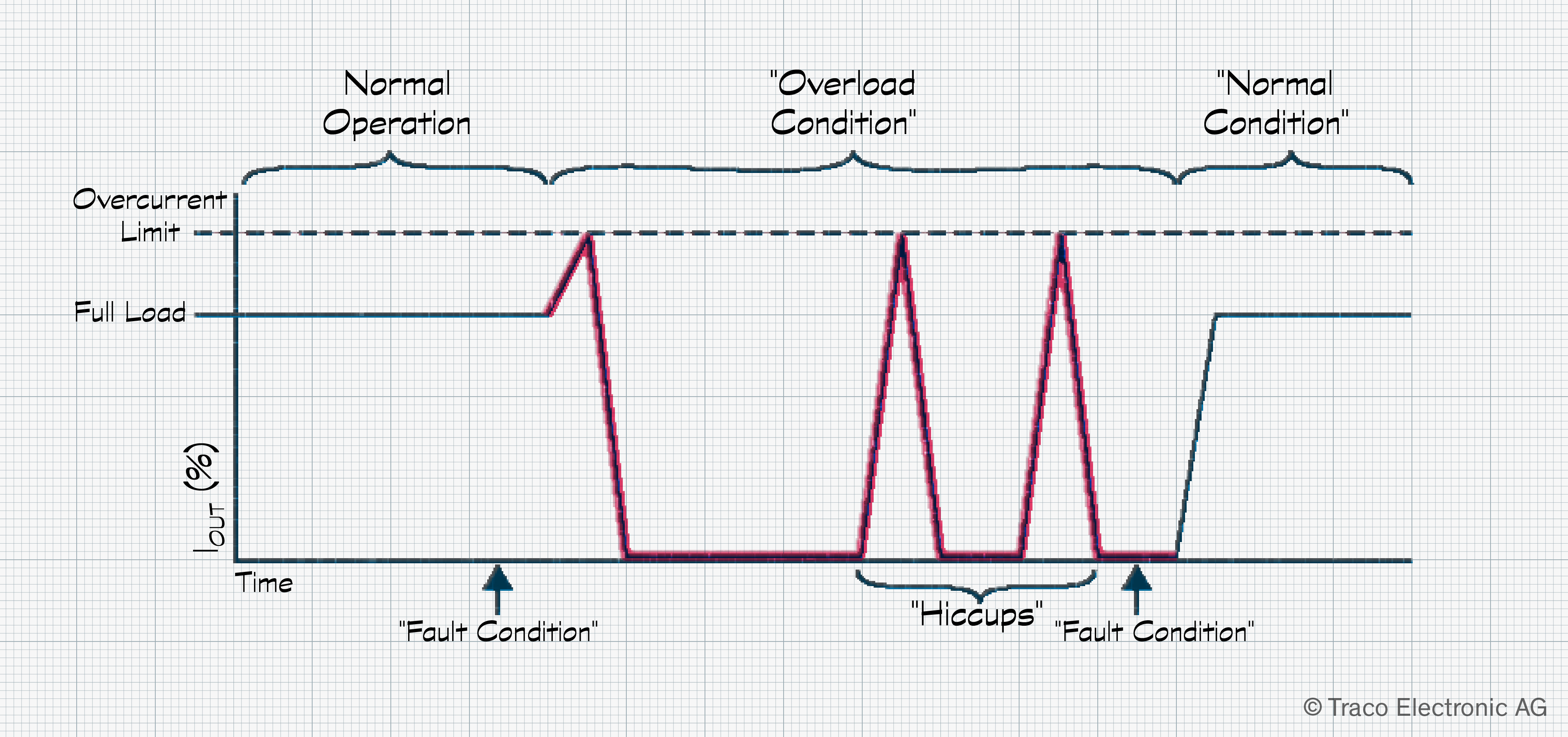

How do hiccup modes protect power supplies?

To avoid such lockout conditions, some designs utilize digitally-controlled hiccup-mode protection. As the name suggests, once the short circuit condition has been detected, the power supply repeatedly attempts to restart its output at regular intervals. Because the output circuitry is switched off, the risk of thermal overload to transistors, MOSFETs, and Schottky diodes is significantly reduced. Again, like fold-back current limiting, there are no standards for the implementation, so the time between restart attempts varies. The period can range from tens of milliseconds to seconds between attempts.

High inrush currents, such as charging capacitors, can also trigger hiccup mode. If the load is not attached, capacitors may charge over a few hiccup cycles, resulting in normal operation. Short circuits over long lengths of cable can also hinder troubleshooting, as the hiccup period needs to be considered after each change, and it may take a moment before the desired voltage is seen.

Should I change a power supply’s internal fuse?

Fuses are another method for protecting power supply outputs. However, they are challenging to specify because, as we have seen, not all high-current conditions are short circuits. Once blown, the correct replacement must be sourced, which may not always be to hand. This is why electronic protection mechanisms are a standard feature of today’s advanced power supplies.

Power supplies feature internal fuses, which are designed to protect against faults. However, it is advisable to contact the supplier for analysis. You must not open or modify a power supply by your own.

To read more of our blogs, click here: www.tracopower.com/blog