What must I consider when specifying my power supply?

In our previous blogs on specifying power supplies, we’ve focused on the output side in part 2 and the input requirements in part 1. However, these have all been electrical specifications. In this final part covering requirements, we’ll look at some other aspects you may need to consider.

Many are environmental, but some are important for manufacturability, such as the soldering profile. Let’s get into the details!

What else is covered in power supply specifications?

A range of further aspects requires your attention when specifying a power supply beyond the electrical requirements. For example, power supplies are not 100% efficient, and the energy lost during conversion is dissipated as heat. In many environments, this will probably not be an issue. But if the ambient temperature where the unit operates is very high, it may be. You will also need to consider humidity, altitude, and atmospheric pressure too. In this next section, we’ll provide some background on when these parameters become important and how they are defined.

Temperature ranges

There are typically two or three key points to consider around temperature. The easiest to define is the storage temperature, providing the upper and lower limit for ambient temperature where the power supply is stored when not in use.

The second is the operating temperature. Again, upper and lower limits are provided for the ambient temperature. Here it is essential to understand that ‘ambient’ is defined with respect to the power supply device. This means that if the unit is built into a cabinet or enclosure, the temperature inside must be considered. If other components in the enclosure also dissipate heat, such as motors or other power converters, the internal temperature can become significant.

Finally, some devices, such as DC/DC converters, may define a limit for their case temperature during operation.

Cooling systems

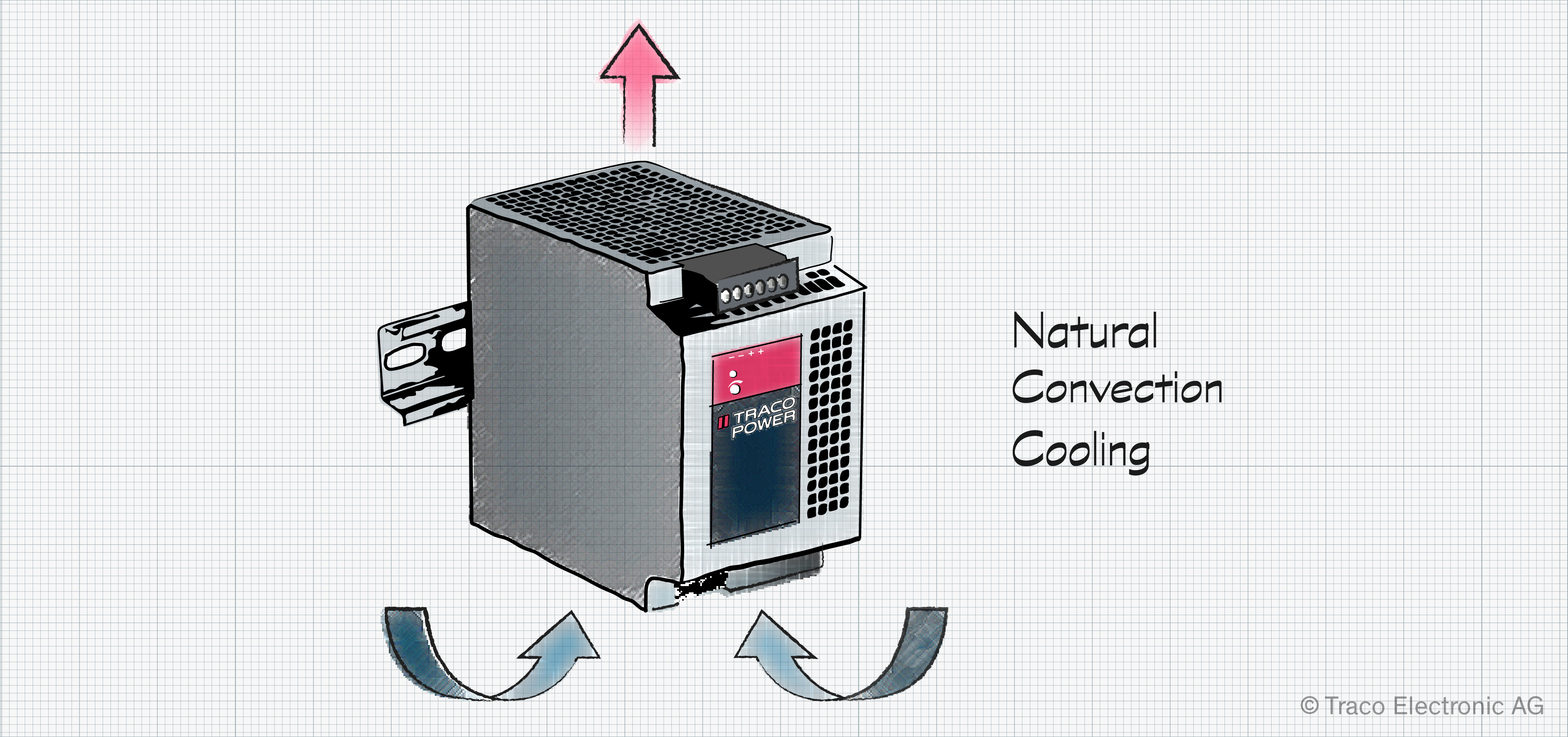

Heat is a critical challenge in most systems handling and controlling power, and efforts are commonly made to deal with this. Specifications may state that a power supply requires ‘natural convection’ cooling. If this is the case, it is expected that air can flow over the unit at around 20 LFM (linear feet per minute) or 0.1 m/s. The word ‘natural’ can cause confusion here, so while there is no demand for a fan, it should also be understood that the air around the unit must not be still. In most applications, this minimal flow rate results from the ‘stack effect,’ the name given to the natural result of hot air rising from the power supply. Should this not be possible, an alternative cooling approach may be necessary.

Some power supplies may require conduction cooling to enhance cooling, and a mounting plate of a specific dimension will be defined in such cases.

If forced cooling is needed, this will be specified in LFM or m/s so that a suitable fan can be sourced.

Relative humidity

The amount of water vapor in the air referenced to the maximum amount it can hold is defined as relative humidity. However, the amount of water the air can accommodate varies with air pressure. In a power supply datasheet, the upper limit of relative humidity under which the unit can be operated is usually given, meaning that it shouldn’t be possible for condensation droplets to form. However, it should also be noted that this is understood to be non-condensing humidity. The value is provided as an upper limit, valid over the operating ambient temperature.

Condensation can still occur at relatively high temperatures at high relative humidity levels. For example, at 95% relative humidity, 60°C ambient temperature, and 2000 MASL (meters above sea level), condensation forms on surfaces under 59°C. If you’re concerned that this may be an issue, various dew point calculators online can help with the math.

Altitude during operation and atmospheric pressure

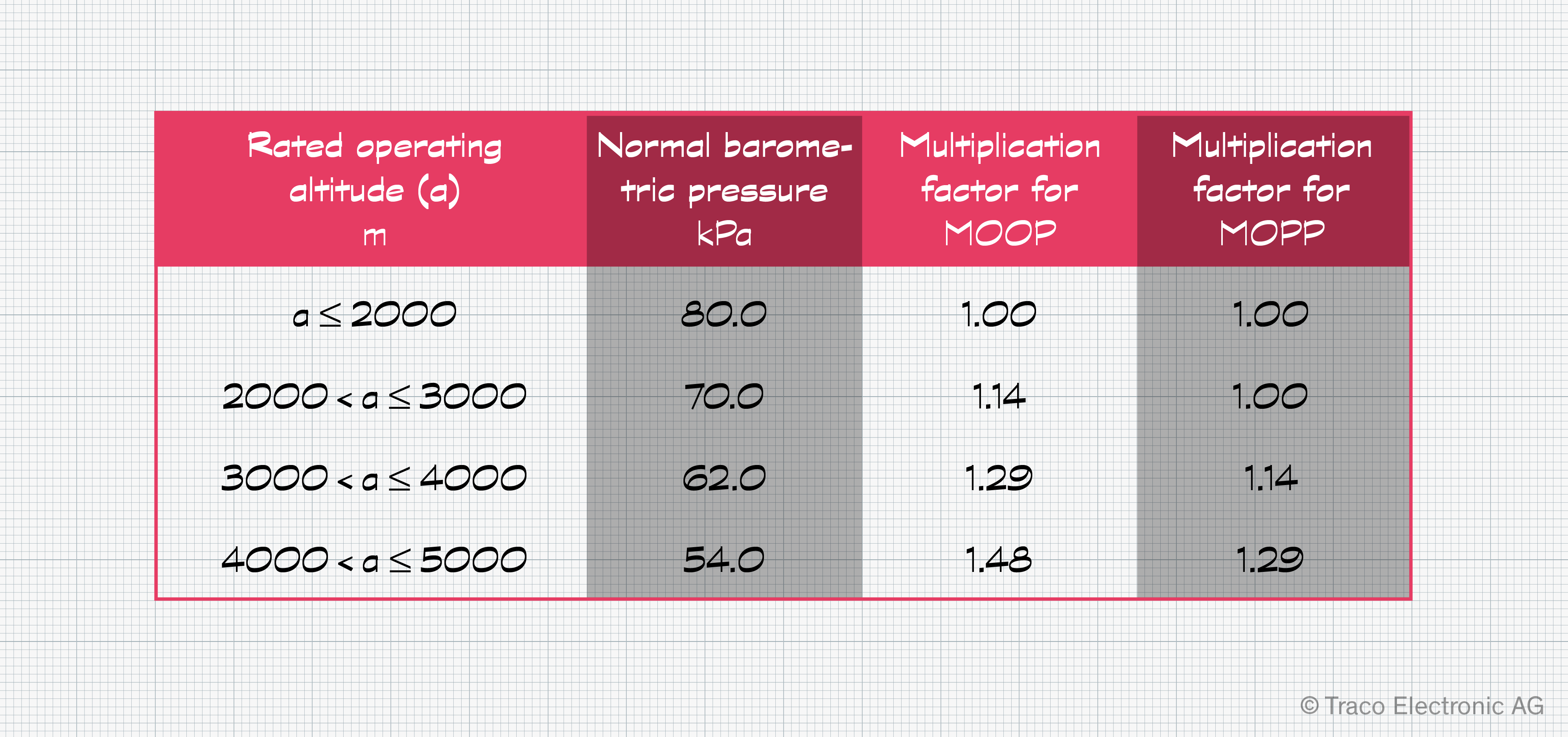

The pressure of air varies with altitude, which, in turn, has an impact on the conductivity of air. If your application is safety-related, the clearance distances will need to be larger when operated at higher altitudes. IEC 60601-1, a medical electrical equipment standard, provides a table of multiplication factors for clearance distances at different altitudes. To summarize, power supplies usually operate at higher altitudes than those given, but the clearance distances implemented will no longer fulfill the safety requirements.

Atmospheric pressure may be given as a range over which the power supply can operate correctly. This can also be used to calculate maximum and minimum operating altitudes.

Reliability

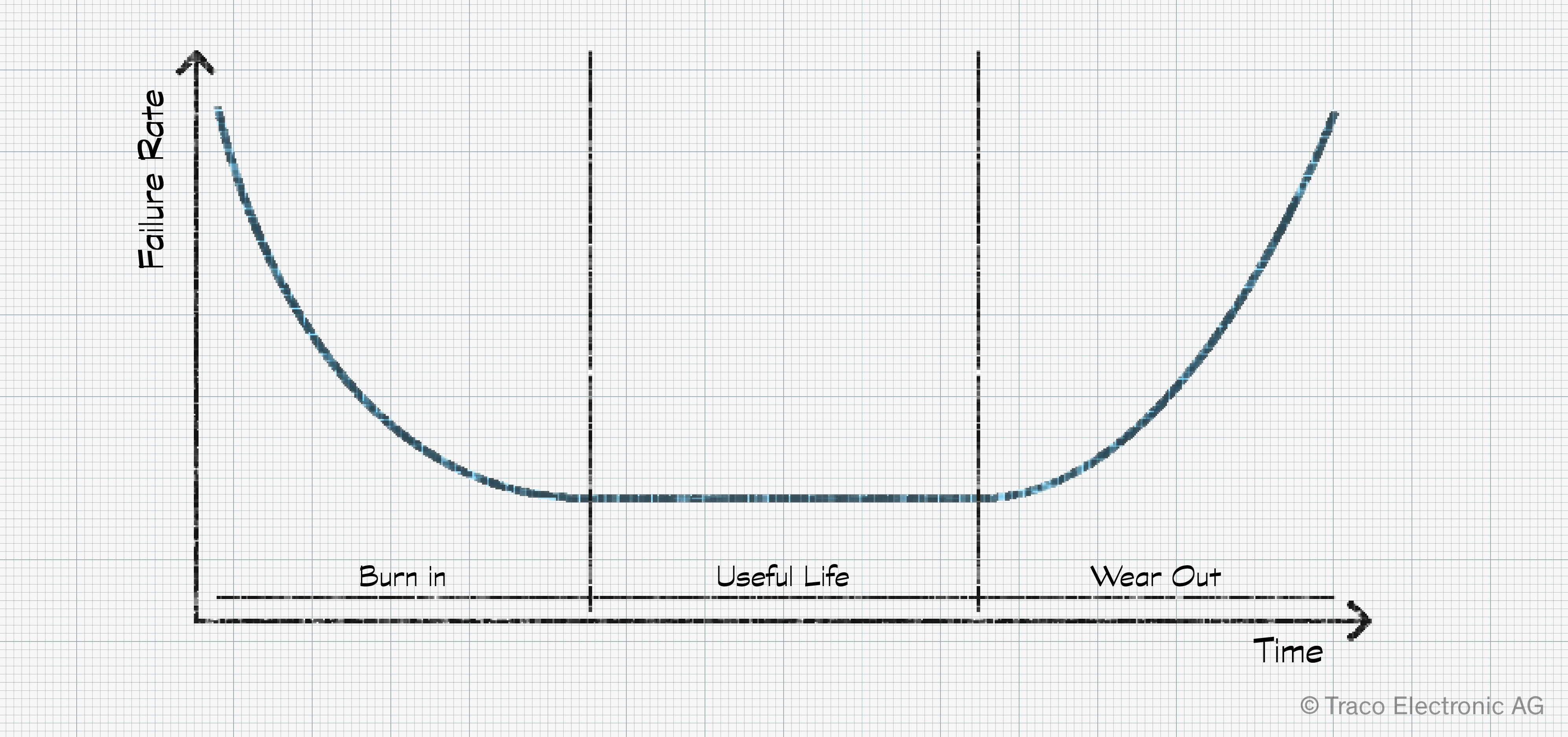

Power supplies are designed and built with diligence and care, but nothing lasts forever. Reliability values are provided so designers can assess the expected lifetime. Typically, these are given in hours (h) of MTBF (mean time between failures).

MTBF is applicable during “useful life” only (it excludes early failures and wearout). MTBF can be determined in many ways, one of which is the MIL-HDBK-217F (military handbook 217F). This particular approach uses the number of components deployed as a metric in its calculations, assuming that using more components decreases reliability and lowers MTBF. MTBF values can range from a few thousand up to millions of hours. So it is important to note: The MTBF time is not the expected lifetime! MTBF is a statistical value of failure intervals during useful life under very specific conditions. However, the actual useful life is usually much shorter than the MTBF value and a failure can potentially occur at any time.

Soldering profile and moisture sensitivity

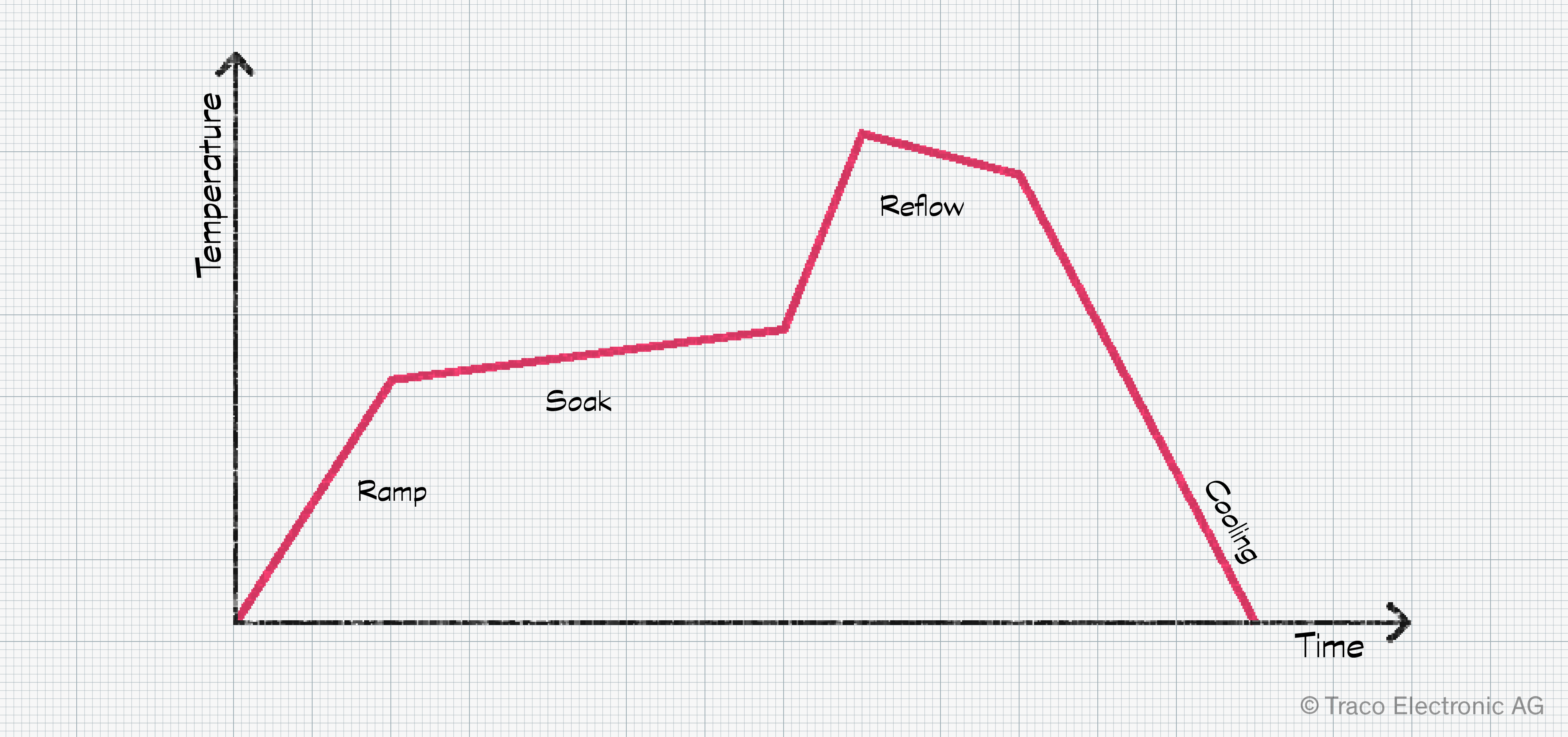

Components are rarely soldered by hand in production, so manufacturing teams must know the maximum temperature and duration allowable for automated wave or vapor phase soldering equipment. The recommended temperature and time may be given simply in numbers or, in other cases, will reference a soldering profile standard (e.g., J-STD-020D).

Surface mount devices (SMD) can be damaged if excessive amounts of moisture penetrate their packaging prior to undergoing soldering processes. The rapid moisture expansion as it heats up can result in delamination and cracks in a component’s packaging. Such components will be delivered in sealed bags and must be processed within a time period defined by their MSL (moisture sensitivity level). Failure to meet this time limit will require the parts to be baked to reduce the moisture content before soldering.

Other specifications

Some environments can place electronics under various physical stresses due to shock and vibration. The limits of what can be withstood will be given in numbers or with reference to a specific standard (e.g., IEC60028-2).

Then there are specifications relating to the protection of the environment. This will include compliance with REACH or RoHS but may also include flammability for railway applications. If relevant, materials used in the construction of the power converter will be provided, such as the PCB, potting compounds, and housing materials.

Power supply specifications: A lot to consider

In our final blog post examining power converter specifications, we covered many of the non-electrical factors that must be considered, from cooling and altitude to humidity and soldering. With that, you and your team should have a handle on almost everything you’ll need to consider when selecting a power supply. However, something is bound to come up for which you cannot find an answer. If so, reach out to our team and ask for support or chat with us at a trade show – we’re always happy to help!

To read our previous blogs covering the general electrical specifications of power converters, please click Part 1 and Part 2.