When do I need an isolated power supply?

In many applications, the power supply converts line voltage AC to a lower voltage DC output suited to the target application. If needed, further DC/DC converters may be employed to deliver lower or higher voltages from this DC supply as required by the system under construction. During regular operation, the user shouldn’t be exposed to hazardous voltages. But, if a spike or transient occurs on the line input, there is a significant risk that high voltages could pass to parts of the application that the user can touch. To provide protection under such conditions, the power supply’s isolation measures ensure end-user safety. However, there are other cases where the isolation requirements are more strictly defined.

What applications define stricter isolation requirements?

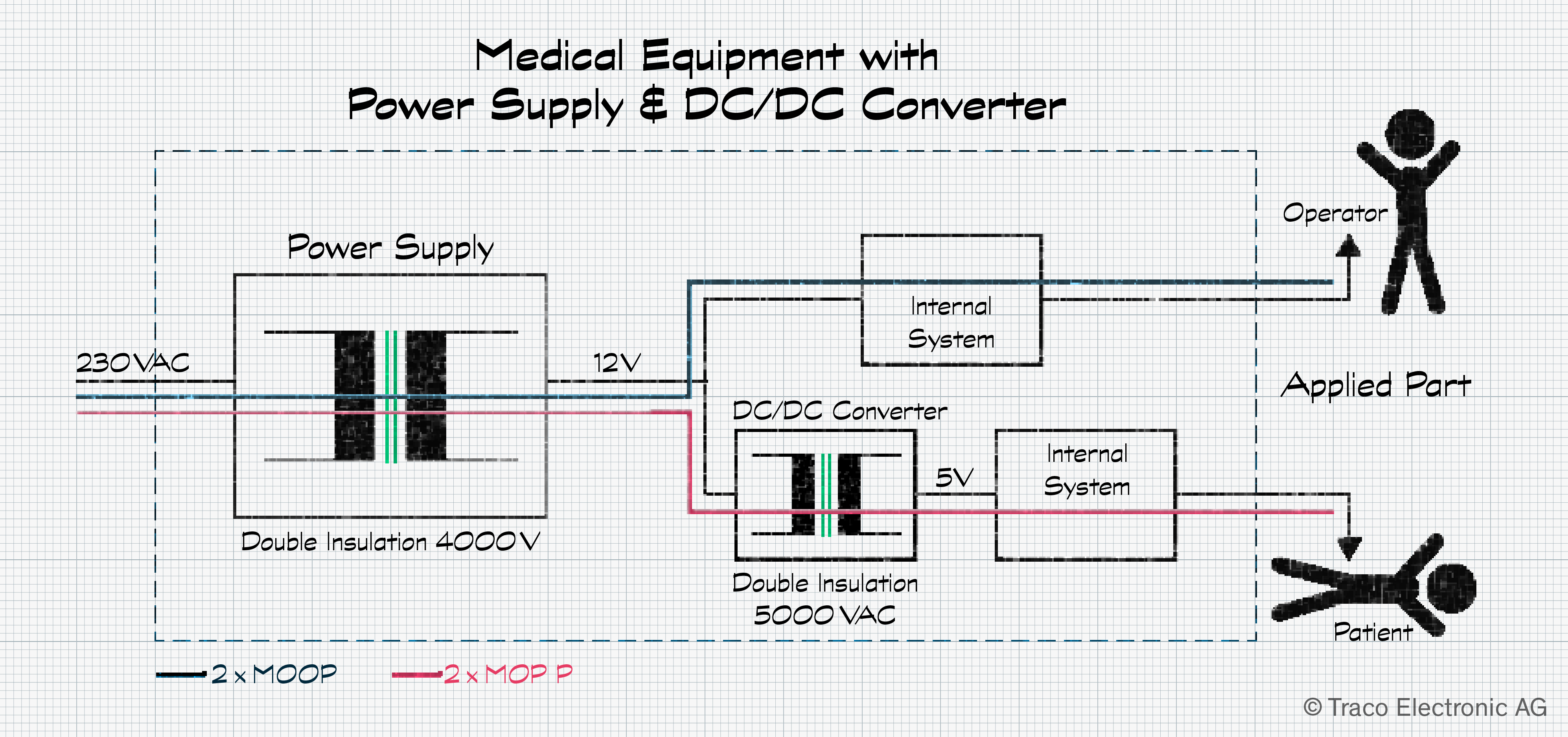

Medical applications are one of several markets where isolation for power supplies are defined in more detail. Patients may be permanently attached to monitoring devices, with electrical sensors affixed to their bodies. Furthermore, they may be unconscious and unable to deal personally with an incident. Such sensors are termed Applied Parts (AP) and are one of several key terms defined in IEC 60601, a standard that defines the requirements for medical electrical and electronic systems.

A Means of Protection (MOP) is needed, which can include safety insulation, creepage distances, air gaps, a protective earth, and other techniques. These are required to protect both the patient (Means of Patient Protection, MOPP) and the operator (Means of Operator Protection, MOOP).

However, isolation is not solely about safety. Sometimes, isolated power supplies are used to resolve problems resulting from ground loops in industrial or audio/visual systems, or to improve electromagnetic compatibility (EMC). They are also found in photovoltaic (PV) systems, energy storage solutions (ESS), household appliances, and audio/visual (AV) and IT applications. Some engineers also use them to generate shifted reference voltages using a DC/DC converter.

How is the isolation in such power supplies implemented?

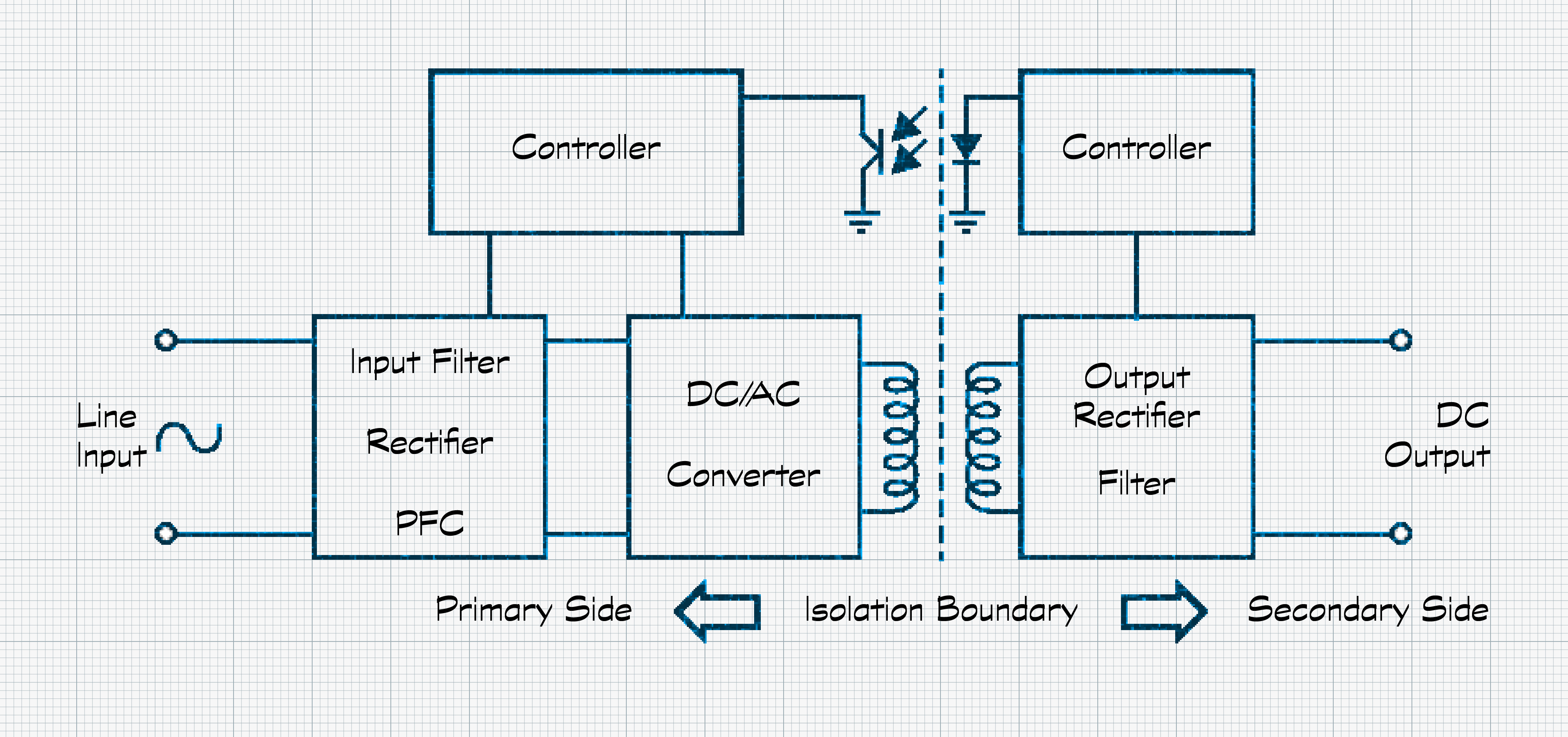

Using a galvanic isolation component, isolated power supplies can ensure that no current passes from the input to the output side. Typically, this is achieved using a suitably specified transformer along with other components, such as optocouplers. This is relatively straightforward for AC/DC power supplies, as transformers are a standard component. However, DC/DC power converters typically require a move to a different topology that ensures a galvanic break between the input and output sides.

Various regulatory bodies, such as the Underwriters Laboratory (UL) in the USA, and the IEC and VDE in Europe, define the insulation level required. For example, in IEC 62368, five categories of electrical insulation are given:

-

Functional Insulation: That required for correct equipment function.

-

Basic Insulation: Provision of basic electric shock protection.

-

Supplementary Insulation: Additional insulation to reduce the risk of shock in the event of basic insulation failure.

-

Double Insulation: Use of both basic and supplementary insulation.

-

Reinforced Insulation: Uses materials with electrical and mechanical properties to achieve double insulation levels with a single insulation layer approach.

The isolation level is defined as a voltage in the power supply’s data sheet and is defined for various temporary conditions, not continuous operation. For example, the unit may be specified to withstand 4000 VAC for 60 seconds between input and output. However, the same device may be specified to withstand 1500 VAC for 60 seconds between the input or the output and the case or PE (protective earth).

What are the disadvantages of isolated converters?

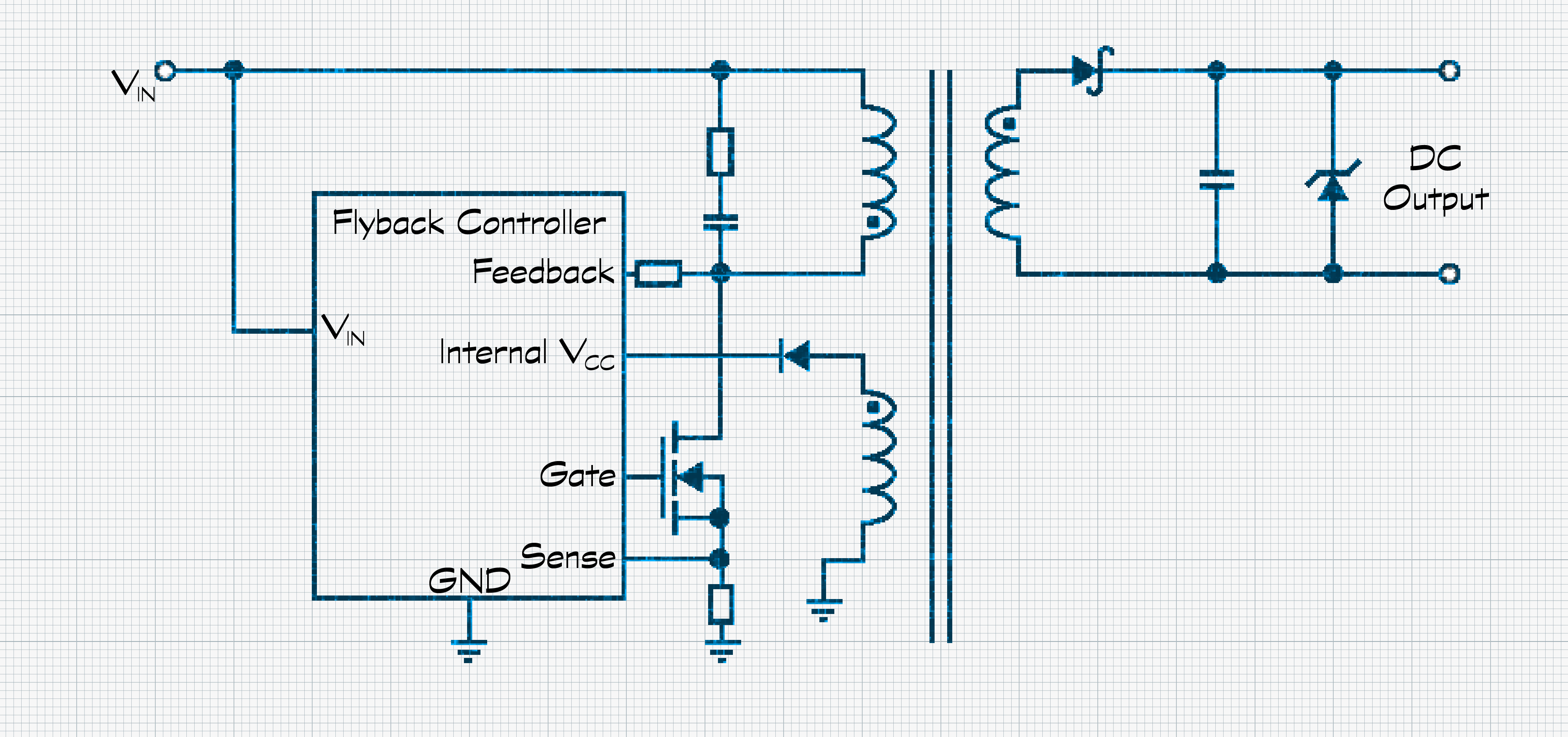

The core challenge in developing an isolated DC/DC converter is its additional complexity compared to a non-isolated design. This impacts everything from development time and component selection to weight and efficiency, resulting in a price premium.

In AC/DC converters, the secondary and primary sides need to share. This includes operational information, such as load, as well as notification of any circuit failures or a short circuit condition. Such data is typically passed using an optocoupler.

For DC/DC converters, a transformer provides the isolation. Unlike off-the-shelf inductors used in a non-isolated converter, this component is likely specifically designed for the application. This adds cost and may demand hand soldering during production. Transformers are also bulky, resulting in a larger and heavier end device for an equivalent level of power delivery. An optocoupler may also be used between the secondary and primary sides to improve regulation and efficiency. However, other approaches are available, such as using a third winding on the transformer. Overall, manufacturing costs for isolated DC/DC converters are typically higher than for non-isolated designs.

Isolated power converters – a must in many applications

While transformer construction continues to improve and design topologies advance, isolated DC/DC power supplies still fall behind their counterparts when it comes to efficiency, regulation, and other performance criteria. For example, non-isolated DC/DC converters can achieve 90% to 99% efficiency, while an isolated DC/DC converter typically lies in the region of 85% to 95%. Thus, it makes sense to consider carefully whether an isolated supply, with its larger size, weight, and cost, is required. Isolated power supplies can help resolve issues with EMI, ground loops, and generation of reference voltages. However, in some applications, such as medical, where protection against hazardous voltages guards users and operators from harm, their use is mandatory.